Series-D

Features

3-Piece Bolted Trough with Bolted Top CoverDesigned to meet the needs of your application. Heavier steel frames and abrasion resistant liners are used, as needed.

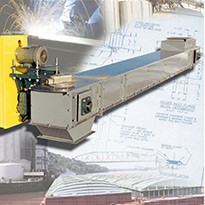

3-Piece Bolted Trough with Bolted Top CoverDesigned to meet the needs of your application. Heavier steel frames and abrasion resistant liners are used, as needed.  Heavy Duty Welded and Forged Steel Drag Chains and SprocketsAvailable in both mild and stainless steel. A wide variety of drag chains are available to meet our safety factors and to meet the conditions of your application.

Heavy Duty Welded and Forged Steel Drag Chains and SprocketsAvailable in both mild and stainless steel. A wide variety of drag chains are available to meet our safety factors and to meet the conditions of your application. Properly Size Flight PaddlesDesigned to meet the volumetric capacity of your application, as well as handle the wear and tear of the application.

Properly Size Flight PaddlesDesigned to meet the volumetric capacity of your application, as well as handle the wear and tear of the application. Industrial Grade Bearings, Motors, and DrivesBrands can be of the customer’s choice or Rapat will provide our standard offering.

Industrial Grade Bearings, Motors, and DrivesBrands can be of the customer’s choice or Rapat will provide our standard offering. Protected Screw Take-UpA mechanical take-up to remove slack from the chain and maintain tension. Proper selection is based on the application requirements.

Protected Screw Take-UpA mechanical take-up to remove slack from the chain and maintain tension. Proper selection is based on the application requirements.

En-Masse ChainOne strand of chain with welded steel flights moving a single mass of material at constant speed.

En-Masse ChainOne strand of chain with welded steel flights moving a single mass of material at constant speed. Single Strand ChainA single strand of chain driven with a single sprocket.

Single Strand ChainA single strand of chain driven with a single sprocket. Dual Strand ChainTwo strands of chain driven by two sprockets. Can be used with en-masse, chain belt, live hopper, scavenger or scraper flight drags.

Dual Strand ChainTwo strands of chain driven by two sprockets. Can be used with en-masse, chain belt, live hopper, scavenger or scraper flight drags. Apron ChainA hinged steel belt driven by two sprockets with steel interlocking apron wings on each edge of the belt.

Apron ChainA hinged steel belt driven by two sprockets with steel interlocking apron wings on each edge of the belt. Chain BeltA dual chain driven by two sprockets and connected at each side of a belt.

Chain BeltA dual chain driven by two sprockets and connected at each side of a belt. Flat Wire ChainA formed metal mesh belting designed to convey either bulk materials or solid units on the top service of the belt.

Flat Wire ChainA formed metal mesh belting designed to convey either bulk materials or solid units on the top service of the belt. Live Hopper ChainA single or dual chain that is designed to pull material from a bulk storage vessel.

Live Hopper ChainA single or dual chain that is designed to pull material from a bulk storage vessel. Scavenger ChainA chain conveyor mounted beneath a belt conveyor that is designed to run at slow speeds to remove fugitive materials from material not contained by the belt conveyor.

Scavenger ChainA chain conveyor mounted beneath a belt conveyor that is designed to run at slow speeds to remove fugitive materials from material not contained by the belt conveyor.  Scraper ChainA chain conveyor that is designed to convey material at the height of the flight.

Scraper ChainA chain conveyor that is designed to convey material at the height of the flight.

Standard InletStandard inlet(s) are designed to feed the conveyor with product. Multiple inlets can be added along a drag conveyors length.

Standard InletStandard inlet(s) are designed to feed the conveyor with product. Multiple inlets can be added along a drag conveyors length.  By-Pass InletBy-Pass inlets are an elongated inlet where the material bypasses the return flights to smoothly enter the product flow and reduce product degradation and wear and tear on the chain.

By-Pass InletBy-Pass inlets are an elongated inlet where the material bypasses the return flights to smoothly enter the product flow and reduce product degradation and wear and tear on the chain. Bend SectionA transition designed to make a horizontal to inclined attitude change in any drag conveyor.

Bend SectionA transition designed to make a horizontal to inclined attitude change in any drag conveyor. Intermediate DischargeA manual, electric, or pneumatic gate that is designed to allow for discharge of material at the intermediate sections of a conveyor.

Intermediate DischargeA manual, electric, or pneumatic gate that is designed to allow for discharge of material at the intermediate sections of a conveyor. Spike RollerA cogged roller that runs in reverse of the chain direction to control the height of material on the chain.

Spike RollerA cogged roller that runs in reverse of the chain direction to control the height of material on the chain.