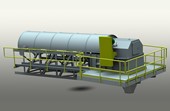

Series-ECTR

Features

Tool-less Top CoversTop covers are easily removed by releasing an over-center clamp and removing the hinged splice cover.

Tool-less Top CoversTop covers are easily removed by releasing an over-center clamp and removing the hinged splice cover. Bolt-On Bottom CoversThese require periodic cleaning to prevent product buildup.

Bolt-On Bottom CoversThese require periodic cleaning to prevent product buildup.  Heavy Duty Industrial Grade Bearings, Drives and MotorsBrands can be of the customer's choice or Rapat will provide our standard offering.

Heavy Duty Industrial Grade Bearings, Drives and MotorsBrands can be of the customer's choice or Rapat will provide our standard offering. Inspection DoorsDoors used to monitor operating conditions and provide access for maintenance.

Inspection DoorsDoors used to monitor operating conditions and provide access for maintenance. Off-The-Shelf CEMA Standard Pulleys and Idlers These components are readily available for quick replacement.

Off-The-Shelf CEMA Standard Pulleys and Idlers These components are readily available for quick replacement.

Channel Support TrussA structural channel support truss can be used to support the Series-ECTR when shorter spans are required between support locations.

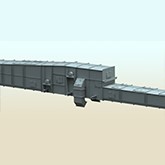

Channel Support TrussA structural channel support truss can be used to support the Series-ECTR when shorter spans are required between support locations. W-Beam Support TrussA structural w-beam support truss designed to span between support locations and meet site loading requirements. Walkway(s) can be supported from the truss, as required.

W-Beam Support TrussA structural w-beam support truss designed to span between support locations and meet site loading requirements. Walkway(s) can be supported from the truss, as required. Box Support TrussA welded structural steel boxed-shaped support truss designed to span between support locations and meet site loading requirements. Walkway(s) can be supported from the truss, as required.

Box Support TrussA welded structural steel boxed-shaped support truss designed to span between support locations and meet site loading requirements. Walkway(s) can be supported from the truss, as required. Gallery Support TrussA square, welded structural steel support truss that a belt conveyor and any optional walkway(s) can sit within. These are also designed to span between ground support locations and can be enclosed with sheeting or left open.

Gallery Support TrussA square, welded structural steel support truss that a belt conveyor and any optional walkway(s) can sit within. These are also designed to span between ground support locations and can be enclosed with sheeting or left open. Transfer TowersA structural steel support tower where one conveyor transitions and feeds into another. These are designed for each application and can include stairways, handrails and platforms.

Transfer TowersA structural steel support tower where one conveyor transitions and feeds into another. These are designed for each application and can include stairways, handrails and platforms. Support BentsA structural steel support frame designed and fabricated to support a conveyor at an elevation and meet the site specific loading requirements.

Support BentsA structural steel support frame designed and fabricated to support a conveyor at an elevation and meet the site specific loading requirements. WalkwaysA platform with a safety handrail that is supported off the side of a conveyor from which a person can walk along the length of a conveyor for maintenance and access. These can be on one or both sides of a conveyor.

WalkwaysA platform with a safety handrail that is supported off the side of a conveyor from which a person can walk along the length of a conveyor for maintenance and access. These can be on one or both sides of a conveyor. Service PlatformsA platform for safely accessing and maintaining key areas of a conveyor.

Service PlatformsA platform for safely accessing and maintaining key areas of a conveyor. Fixed TripperA device that allows for material to be discharged prior to the end of the conveyor.

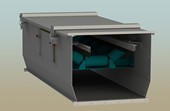

Fixed TripperA device that allows for material to be discharged prior to the end of the conveyor. Scavenger DragAn integrated drag conveyor mounted below the belt conveyors return idlers and designed to make the conveyor self-cleaning. This in an option used in dusty applications.

Scavenger DragAn integrated drag conveyor mounted below the belt conveyors return idlers and designed to make the conveyor self-cleaning. This in an option used in dusty applications. Gravity Take UpsA device that automatically adjusts using a counterweighted pulley to maintain proper tension on the belt. These are generally used on longer conveyors where mechanical take-ups are no longer practical.

Gravity Take UpsA device that automatically adjusts using a counterweighted pulley to maintain proper tension on the belt. These are generally used on longer conveyors where mechanical take-ups are no longer practical. Chutes/Transitions Customized chutes and transitions are designed to move product to and from conveyors to other conveyors and process equipment. These are available with a variety of wear liner options depending on the material being conveyed.

Chutes/Transitions Customized chutes and transitions are designed to move product to and from conveyors to other conveyors and process equipment. These are available with a variety of wear liner options depending on the material being conveyed. Impact BedsA series of cushioned bars used to absorb loading forces under a conveyor belt in the loading zone. These vary depending on the material being conveyed and the distance of the product being dropped onto the belt.

Impact BedsA series of cushioned bars used to absorb loading forces under a conveyor belt in the loading zone. These vary depending on the material being conveyed and the distance of the product being dropped onto the belt. Skirting Replaceable rubber seals that contact the conveyor belt to contain product through the loading area. These are adjustable and can be lined with a variety of wear liners.

Skirting Replaceable rubber seals that contact the conveyor belt to contain product through the loading area. These are adjustable and can be lined with a variety of wear liners. Mine Duty & Engineered Class Pulleys Mine duty pulleys are heavier duty than standard pulleys for harsh environments. When mine duty pulleys still don’t meet the required belt tensions and durability requirements of an application, pulleys can be engineered to meet those demands.

Mine Duty & Engineered Class Pulleys Mine duty pulleys are heavier duty than standard pulleys for harsh environments. When mine duty pulleys still don’t meet the required belt tensions and durability requirements of an application, pulleys can be engineered to meet those demands. Belt CleanersA device that uses a tensioned blade mounted on a supporting structure to remove material that clings to the belt beyond the normal discharge point. The material, size and tension are determined by the product and its characteristics. These are often mounted inside the discharge hood so product cleaned off belt falls into the discharge.

Belt CleanersA device that uses a tensioned blade mounted on a supporting structure to remove material that clings to the belt beyond the normal discharge point. The material, size and tension are determined by the product and its characteristics. These are often mounted inside the discharge hood so product cleaned off belt falls into the discharge. WashboxA device that uses pressurized water and a series of belt cleaners to clean especially tacky material from a belt.

WashboxA device that uses pressurized water and a series of belt cleaners to clean especially tacky material from a belt. Belt ScaleA device that weighs or measure the amount of product moved on a belt conveyor. These vary per application and accuracy requirements.

Belt ScaleA device that weighs or measure the amount of product moved on a belt conveyor. These vary per application and accuracy requirements. Belt MagnetA device for removing ferrous metals from the product as it moves on a belt conveyor in order to prevent damage to downstream equipment. Size and mounting location vary per application.

Belt MagnetA device for removing ferrous metals from the product as it moves on a belt conveyor in order to prevent damage to downstream equipment. Size and mounting location vary per application. Water Deluge LinesPressurized water lines with diffusers that can be attached to a conveyor to flood the product with water in order to suppress dust and extinguish potential fires. This is a unique option for specific applications.

Water Deluge LinesPressurized water lines with diffusers that can be attached to a conveyor to flood the product with water in order to suppress dust and extinguish potential fires. This is a unique option for specific applications. Grease LinesAllows for greasing bearings from remote locations.

Grease LinesAllows for greasing bearings from remote locations.